Feature – Tube Bending Lean Manufacturing

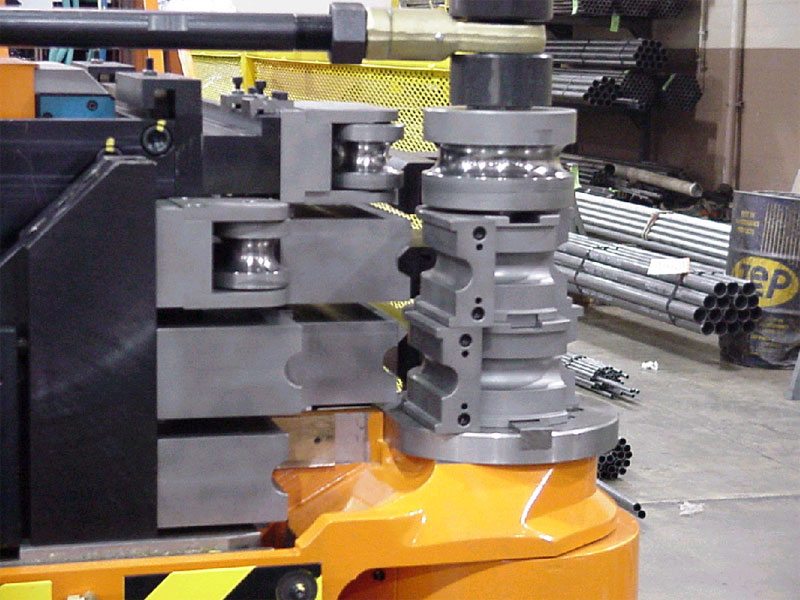

Watson Engineering, Inc. has over 35 years’ experience in metal tube bending for low volume, small diameter tube fabrication. Watson specializes in mandrel bent tube and pipe in 1/4″ (6 mm) to 3.0″ (76.2 mm) outside diameter in a round, square or rectangular shapes for a prototype to production. Small jobs and one-time orders are gladly accepted. [More Info]

Metal Tube Bending Lean Manufacturing Capability

View our Tube Bending Tube Bending – Lean Manufacturing video >>

When speed and precision count, customers turn to Watson. Furthermore, the company takes pride in offering competitive pricing and fast turnaround. Additionally, experienced staff offers rapid prototypes and high-quality production parts for industries of all types. Consequently, rapid prototyping enables Watson to bring your product to market quickly and efficiently. This is done by decreasing product development time while simultaneously providing manufacturing methods and functional performance feedback. Watson has always had a “CAN DO” philosophy and can offer solutions for all of your metal tube bending requirements.

Furthermore, Watson’s expertise lies in the construction, heavy equipment, automotive, motorcycle, and transport industries. Watson focuses on fabricating complete tube assemblies to its customers’ drawings and specifications. In addition, Watson performs a wide range of operations including end forming, welding, brazing, swaging, flaring, assembly, and finishing.

Furthermore, Watson’s expertise lies in the construction, heavy equipment, automotive, motorcycle, and transport industries. Watson focuses on fabricating complete tube assemblies to its customers’ drawings and specifications. In addition, Watson performs a wide range of operations including end forming, welding, brazing, swaging, flaring, assembly, and finishing.

Contact our sales estimators for more information, or fill out a request for quote today!