Powder Coat Painting

Powder coat painting staff Watson Engineering Inc, Piedmont SC paint line members, recently achieved an unprecedented LEVEL 5 rating from Caterpillar’s Audit Team. As a result, this is an excellent example of Watson Engineering, Inc.’s team “Exceeding Expectations.”

Powder Coat Painting Level 5 Certification

CAT’s Auditors have to go through extensive auditor training before being selected for the CAT Customer Acceptance Validation (CAV) Audit Team. However, the auditors must be capable of determining the gap analysis requirements necessary for a CAV Gap Analysis. Therefore, the strict process means using the Benchmarking Guide for Painting Process (BGPP) questionnaire to assure conformance to quality requirements.

The audit is then conducted by CPS Paint Engineering Team or by CPS Certified Auditors. Furthermore, the review consists of no less than 53 segments. Also, each segment has a numerical rating that within that rating system has a weighted mathematical formulation. In essence, it is black/white, mathematically driven, with little to no wiggle room; therefore, removing auditor bias. Consequently, the audit is fact based/driven. Additionally, the audit reviews raw material suppliers to outgoing quality performance. For example pre-treatment systems, chemical, training, lighting, powder(s), hanging/nesting techniques, prep/package, labeling, masking, air filtration, inspection equipment, etc. Most Noteworthy, this is why their lead auditor said, “

Consequently, the audit is fact based/driven. The audit reviews raw material suppliers to outgoing quality performance. Therefore, auditors inspect pre-treatment systems, chemical, training, lighting, powder(s), hanging/nesting techniques, prep/package, labeling, masking, air filtration, inspection equipment, etc. Most Noteworthy, this is why their lead auditor said, “CAT has only had two (2) suppliers in their history ever to achieve a Level 5, because of the audit’s robustness.”

Powder Coat Painting

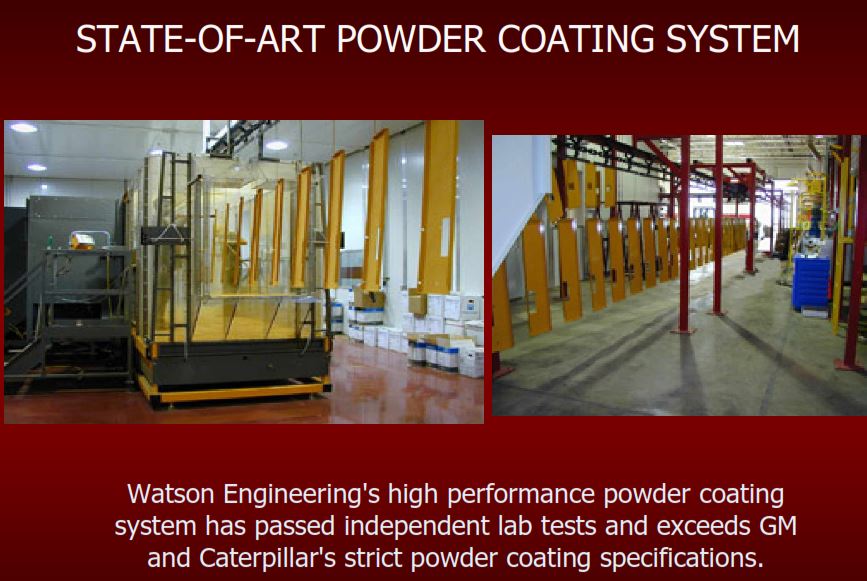

Powder coat painting allows Watson Engineering, Inc. the ability to specialize in custom color, finish selection, and application. Also, this includes high-temperature powders.

Powder coat painting allows Watson Engineering, Inc. the ability to specialize in custom color, finish selection, and application. Also, this includes high-temperature powders.

While powder coating surfaces of metal parts makes an attractive look, it also create a more durable finish. Besides, powder coating makes parts more resistant to chipping, corrosion, scratching, fading, and wearing, than other finishes. As a result, colors stay bright and vibrant longer.

Especially relevant is that color selection for powder coating is virtually limitless. Also, finishes can be topped off with high or low gloss, metallic, and clear coating. Additionally, numerous finishing textures available.

Additionally, Watson Engineering’s high-performance powder coat painting system has passed independent lab tests and exceeds Ford, General Motors, Caterpillar and other OEM’s strict powder coating specifications.